1. Digitise objects

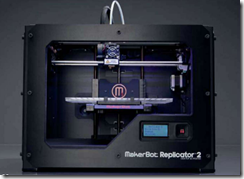

If you have a cheap 3D printer, you'll probably need a tool to scan objects you want to reproduce. Enter the MakerBot Digitizer, a 3D desktop scanner announced in March. The Digitizer will let you scan small household objects, creating 3D design files that can be shared, backed up, and reproduced. Pairing a Digitizer with a 3D printer could let you 'back up' physical items and print replacement parts as necessary, or make modifications to better suit your needs.

2. It's additive

A 3D printer extrudes tiny layers of a single

material - plastic, typically - again and again, to build a 3D object. The process is known as additive manufacturing, and it can be much more efficient, and cheaper and faster, than traditional subtractive manufacturing, where engineers cut parts from larger pieces of material. Consumer-grade 3D printer costs are dropping so fast that, by 2016, analysts say, enterprise-class 3D printers may cost less than a new computer.

3. Build better bones

3D printing lets doctors quickly design and print implants custom-tailored to a patient's physiology. Earlier this year, US surgeons

replaced 75% of a patient's skull with an FDA- approved 3D-printed replica. Scientists claim that 3D printing produces a better-fitting implant than more traditional metal plates, and 3D-printed implants can also be etched with surface or edge details that encourage cell growth and allow bone tissue to attach and heal more easily.

4. No printer required

As cool as 3D printing is, picking up an actual 3D printer for home use is still a pretty expensive investment. If you have an idea for a new object but don't have the time or money to sink into 3D printing as a hobby, you can upload your model to a 3D printing service such as Shapeways or Sculpteo and pay them to print and ship it to you. You'll still need to learn how to design a 3D model, but most 3D printing services offer tutorials and examples on their websites to help you get started.

5. Not just plastic

Most consumer-grade 3D printers can print only plastic. Industrial-grade 3D printers are more versatile; the Objet Connex printers, for example, can print objects made of up to 14 different materials. The result: objects with flexible joints, or even a translucent rubbery hand over a rigid skeletal structure. Multi-material printers are still too expensive for home use, but in the near future, medical offices might print out models of patients' bones sourced from their X-rays.

0 comments:

Post a Comment